M. Holland’s 3D Printing Group Partners with EOS on SLS and Other Materials

The distribution agreement grants access to high-performance selective laser sintering (SLS) materials.

Northbrook, Ill., December 3, 2020: M. Holland Company, a leading distributor of thermoplastic resins and 3D printing materials, announced its 3D Printing group has partnered with Advanced Laser Materials (ALM) and EOS North America to distribute selective laser sintering (SLS) materials. The agreement marks M. Holland’s first venture in the SLS space. It will allow the company to better support OEMs and injection molders using SLS and businesses interested in adopting this technology.

The North American distribution agreement includes powdered polymers for SLS printing, several additive manufacturing materials compatible with a wide variety of 3D printers, access to standard polymer materials from EOS and custom solutions developed by the ALM engineering team.

“Our partnership with ALM was a natural fit. Offering SLS technology materials and solutions is important to broaden options for our clients and ALM’s consultative approach complements the way we do business,” said Haleyanne Freedman, market manager, 3D Printing at M. Holland. “ ALM delivers strong customized material offerings focused on application and technical requirements, which equips us with an expanded suite of solutions and technical information to solve tough application problems for injection molders.”

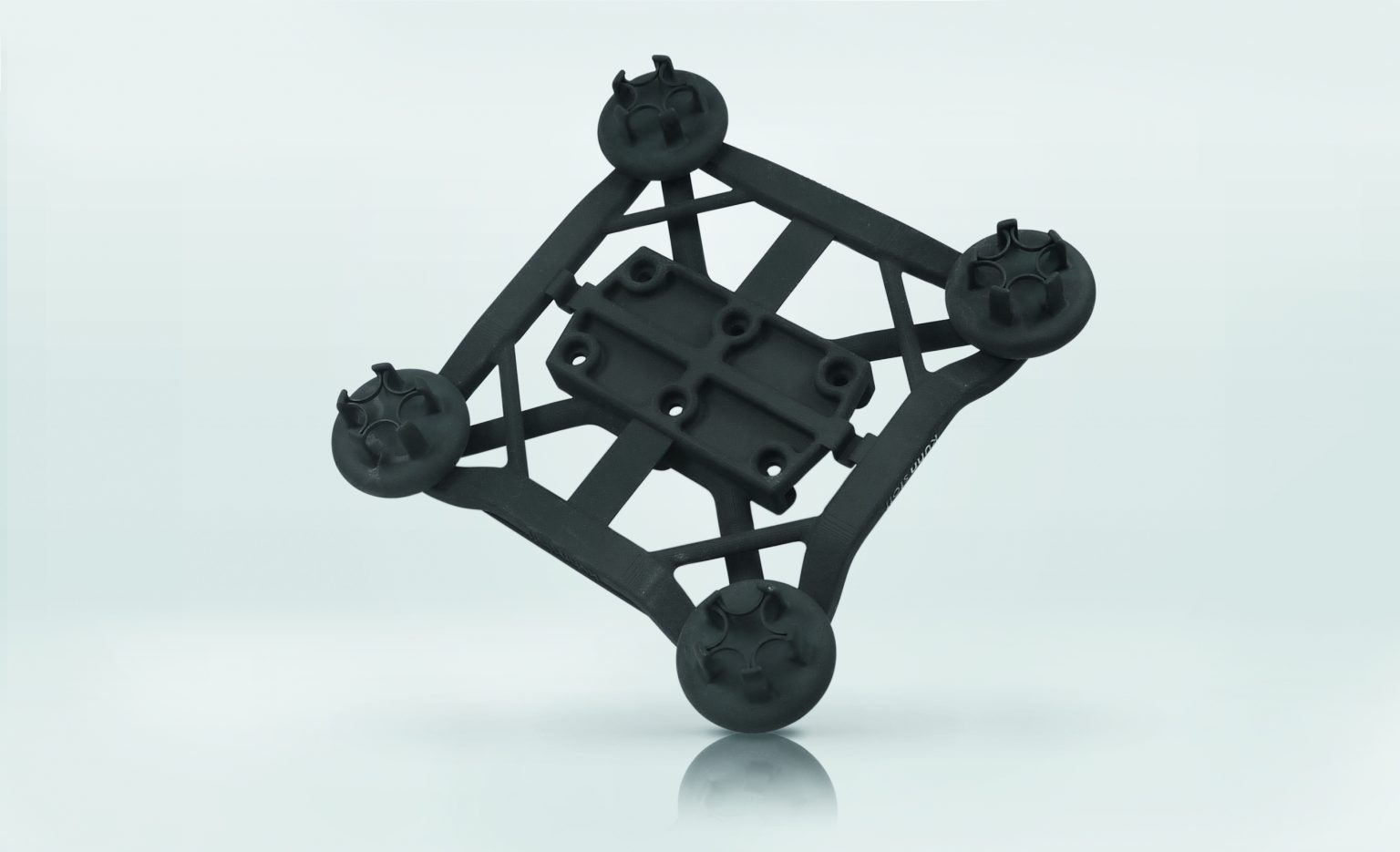

Powder bed-based SLS is a rapidly expanding technology for businesses to implement for production applications. The process is fast, efficient and accurate, offering highly repeatable results that can produce large batches of parts and fine features. When first introduced, SLS polymer printing was primarily based on nylon material, but today many more applications require this technology. In addition to nylon, production involving SLS can use materials including polyamide (PA), polyetherketoneketone (PEKK), polypropylene (PP), thermoplastic polyurethane (TPU), thermoplastic elastomer (TPE) and more.

“At ALM, our passion is creating the best powder-based materials for additive manufacturing to meet the unique specifications of our clients and allowing them to get creative with their applications,” said Darin Chartier, VP Life Cycle Solutions, at EOS North America. “Through our agreement with M. Holland’s 3D Printing group, we are collectively broadening what is possible through selective laser sintering 3D printing technology — reaching new markets and helping drive new applications.”

This partnership strengthens M. Holland’s ever-growing 3D Printing portfolio, which also features offerings from suppliers including Braskem, BASF, Henkel and more. For a complete list of offerings from M. Holland’s 3D Printing group, visit mholland.com.

ALM is a wholly-owned subsidiary of EOS Group, a worldwide technology supplier in industrial 3D printing of metals and polymers.

ABOUT M. HOLLAND

M. Holland is a leading international distributor of thermoplastic resins, providing suppliers with the most strategic channels to market, offering innovative sourcing and supply chain solutions to our clients, and helping people lead rewarding careers. M. Holland’s 3D Printing group offers manufacturers cross-industry knowledge, advice and unbiased consultative expertise on applications, materials and equipment for additive manufacturing. Since 1950, a deep commitment to personal relationships has formed the core of the company’s heritage, its culture, and its vision. Headquartered in Northbrook, Illinois, M. Holland has over $1 billion in annual sales and sells to more than 4,000 customers annually. To learn more, visit www.mholland.com. Follow M. Holland on Twitter, LinkedIn, and Facebook.

ABOUT EOS NORTH AMERICA

EOS North America is a business of EOS, the world’s leading technology supplier in the field of industrial 3D printing of metals and polymers. Formed in 1989, the independent company is pioneer and innovator for comprehensive solutions in additive manufacturing. Its product portfolio of EOS systems, materials, and process parameters gives customers crucial competitive advantages in terms of product quality and the long-term economic sustainability of their manufacturing processes. Furthermore, EOS customers benefit from deep technical expertise in global service, applications engineering and consultancy.

ABOUT ALM

Advanced Laser Materials (ALM) specializes in material research, development and consultation for industrial 3D printing and additive manufacturing. Founded in 2004, ALM remains focused on providing customers with application-specific, quality-tested materials and engineering support to meet the most complex product specifications and production requirements. ALM offers the largest selection of laser sintering solutions with onsite capabilities to produce standard and specialized materials in varying quantities. Based in Temple, Texas, ALM is a fully owned subsidiary of EOS Group.

FOR ADDITIONAL INFORMATION CONTACT:

Sami Sauerman

INK (for M. Holland)

mholland@ink-co.com

715.965.2854